|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Do you know the NEC requirements for sizing junction boxes and pull boxes for conductor sizes 4 AWG and larger?

Figure 01

|

|

|

Figure 01

|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Do you know the NEC requirements for sizing junction boxes and pull boxes for conductor sizes 4 AWG and larger?

Conductor damage during installation is one consequence of undersizing junction and pull boxes. This damage is often not apparent until post-installation cable testing. Then after the boxes are replaced, the defective conductors are replaced. This is an inefficient and expensive way to do an electrical installation.

So while the NEC box size requirements help to prevent hazards to people and property, following them also contributes to on-time job completion, reduced waste, and maintains budget. If there is no conductor testing prior to turnover, you can get by with a defective installation and hope the blame for the premature failure goes to something other than your work. But if someone who knows the requirements examines the installation, those undersized boxes will put your work squarely in the crosshairs of blame.

Sizing rules

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

- Straight pulls. A conductor that enters one wall of a box and leaves through the opposite wall is a straight pull. The minimum distance from the raceway entry to the opposite wall is eight times the trade size of the largest raceway.

- Angle pulls. A conductor that enters one wall and leaves through an adjacent one is an angle pull. The minimum distance from the raceway entry to the opposite wall is six times the trade size of the largest raceway, plus the sum of the trade sizes of the remaining raceways on the same wall and row.

- U pulls. A conductor that enters and leaves from the same wall is a U pull. The minimum distance from the raceway entry to the opposite wall is six times the trade size of the largest raceway, plus the sum of the trade sizes of the remaining raceways on the same wall and row.

- Splices. When conductors are spliced, the minimum distance from where the raceways enter to the opposite wall is six times the trade size of the largest raceway, plus the sum of the trade sizes of the remaining raceways on the same wall and row.

- Rows. Where there are multiple rows of raceway entries, you calculate each row individually and then use the row that results the largest distance calculation.

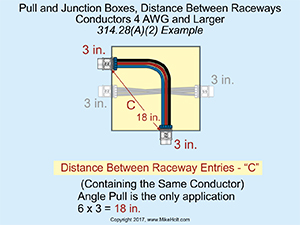

- Distance between raceways. The minimum distance between raceways enclosing the same conductor is six times the trade size of the largest raceway, measured from the nearest edge of one raceway entry to the nearest edge of the other raceway entry. The locknut or bushing doesn't apply to this calculation

When conductors enter an enclosure with a removable cover, such as a conduit body or wireway, the minimum distance from the raceway entry to the removable cover is the bending distance listed in Table 312.6(A) for one conductor per terminal [314.28(A)(2) Ex, 366.58, 376.23, and 378.23].

Pull box example 1

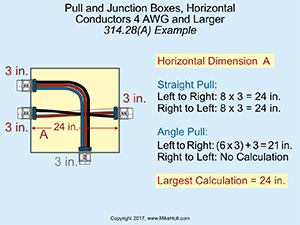

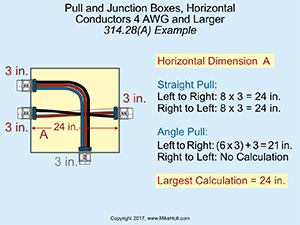

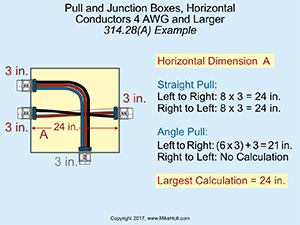

A junction box contains two 3 inch raceways on the left side, one 3 inch raceway on the right side, and one 3 inch raceway on the bottom. The conductors from the lower 3 inch raceway on the left wall are pulled through the 3 inch raceway on the right wall. The conductors from the upper 3 inch raceways on the left wall are pulled through the 3 inch raceway at the bottom of the pull box. Tip: carefully draw the junction box, raceways and where the conductors are run. Figure 01

| ▶ Horizontal dimension

Question: What's the horizontal dimension of this junction box?‚

(a) 18 in. (b) 21 in. (c) 24 in. (d) 30 in.

|

|

Figure 01 |

Answer: (c) 24 in. [314.28]

| Left to Right Straight Pull |

8 × 3 in. = 24 in. |

| Right to Left Straight Pull |

8 × 3 in. = 24 in. |

| Left to Right Angle Pull |

(6 × 3 In.) + 3 in. = 21 in. |

| Right to Left Angle Pull |

No Calculation |

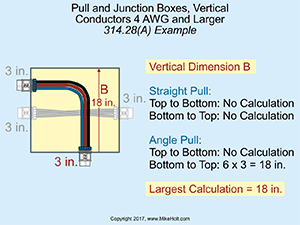

▶ Vertical dimension

Question: What's the vertical dimension of this junction box? ‚Figure 02

(a) 18 in. (b) 21 in. (c) 24 in. (d) 30 in.

|

|

Figure 02 |

Answer: (a) 18 in. [314.28]

| Top to Bottom Straight |

No Calculation |

| Bottom to Top Straight |

No Calculation |

| Top to Bottom Angle |

No Calculation |

| Bottom to Top Angle |

6 × 3 in. = 18 in. |

▶ Distance between raceways

Question: What's the minimum distance between the two 3 inch raceways containing the same conductors?‚Figure 03

(a) 18 in. (b) 21 in. (c) 24 in. (d) 30 in.

|

|

Figure 03 |

Answer: (a) 18 in. [314.28]

6 × 3 in. = 18 in.

|

Pull box example 2

A pull box contains a 2 inch and a 3 inch raceway on the left side, a 3 inch raceway on the top, and a 2 inch raceway on the right side. The 2 inch raceways are a straight pull and the 3 inch raceways are an angle pull. Remember! Draw the junction box, raceways and where the conductors are run.

|

▶ Horizontal dimension

Question: What's the horizontal dimension of this junction box? ‚

(a) 20 in. (b) 24 in. (c) 28 in. (d) 30 in.

Answer: (a) 20 in. [314.28(A)(2)]

| Left to Right Straight Pull |

8 × 2 in. = 16 in. |

| Right to Left Straight Pull |

8 × 2 in. = 16 in. |

| Left to Right Angle Pull |

(6 × 3 in.) + 2 in. = 20 in. |

| Right to Left Angle Pull |

No Calculation |

▶ Vertical dimension

Question: What's the vertical dimension of this junction box? ‚

(a) 14 in. (b) 18 in. (c) 21 in. (d) 26 in.

Answer: (b) 18 in. [314.28(A)(2)]

| Top to Bottom Straight |

No Calculation |

| Bottom to Top Straight |

No Calculation |

| Top to Bottom Angle |

6 × 3 in. = ‰18 in. |

| Bottom to Top Angle |

No Calculation |

▶ Distance between raceways

Question: If two 3 inch raceways contain the same conductors, what's the minimum distance between these raceways?‚

(a) 18 in. (b) 21 in. (c) 24 in. (d) 30 in.

Answer: (a) 18 in. [314.28(A)(2)]

6 × 3 in. = 18 in.

|

Sizing tips for pull boxes and junction boxes

When sizing pull boxes and junction boxes, follow these suggestions:

Step 1: Organize and always draw out the problem.

Step 2: Calculate the horizontal distance(s):

- Left to right straight calculation

- Right to left straight calculation

- Left to right angle or U pull calculation

- Right to left angle or U pull calculation

Step 3: Calculate the vertical distance(s):

- Top to bottom straight calculation

- Bottom to top straight calculation

- Top to bottom angle or U pull calculation

- Bottom to top angle or U pull calculation

Step 4: Calculate the distance between raceways enclosing the same conductors.

Know the system

All of these rules are based on the characteristics of standard electrical conductors and thus apply only to raceway systems for electrical conductors. Many types of cables, such as fiber-optic for example, have a much higher minimum bend radius than electrical conductors of the same diameter. You don't size the boxes for these as if you were installing electrical power conductors.

Often, the same engineering team is tasked with all the box sizing for all systems. If all the box sizing is based on 314.28 regardless of what's being run, the boxes will probably be undersized for raceway systems containing signal cabling or anything other than electrical power conductors.

At an Ohio nuclear power plant, some signal cables for the reactor protection system had a 3 foot bend radius but were run in raceway with 18-inch boxes based on NEC requirements for electrical power conductors. The mere act of pulling the cables into those boxes damaged the cables and caused them to fail the acceptance testing.

The cables were very costly, so after the first test showed a 100% failure rate the reactor protection system test engineers stopped testing to investigate possible failure causes. During a walk-thru, they saw the undersized pull box. The design engineer would not have made this mistake if he'd clearly separated the electrical power conductor raceway system design from signal cabling raceway system design.

Perhaps the most important thing you can do when sizing boxes is to make sure you understand the application. We mentioned you need to avoid applying NEC box sizing rules to signal cabling systems. Another aspect of the application is to understand the application environment. For example, will the box fit at the location you've selected for it? Can it safely and reasonably be serviced there? Never attempt to design in an information vacuum. Know the system, that's what requests for information are for!

|