|

Note: The answers to these questions are based on the 2017 NEC®.

Underlined text indicates a change in the rule for the 2017 NEC.

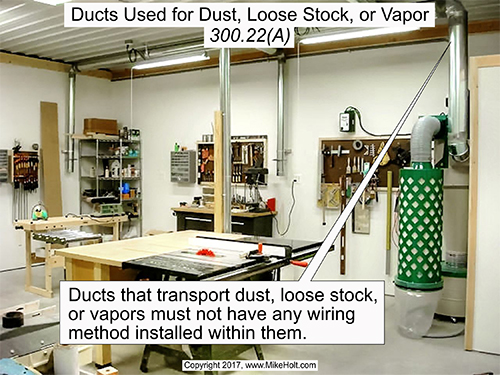

Q1. What are the Code rules regarding wiring in ducts used to transport dust, loose stock, or vapors?

A1. Ducts that transport dust, loose stock, or flammable vapors must not have any wiring method installed within them [300.22(A)]. Figure 01

Q2. What are the Code rules regarding wiring installed in ducts specifically fabricated for environmental air?

A2. Equipment is only permitted within the duct specifically fabricated to transport environmental air if necessary for the direct action upon, or sensing of, the contained air. Equipment, devices, and/or illumination are only permitted to be installed in the duct if necessary to facilitate maintenance and repair. Luminaires must be of the enclosed gasketed-type. [300.22(B)].

Permitted wiring methods include Type MC Cable that has a smooth or corrugated impervious metal sheath without an overall nonmetallic covering, electrical metallic tubing, flexible metallic tubing, intermediate metal conduit, or rigid metal conduit without an overall nonmetallic covering can be installed in ducts specifically fabricated to transport environmental air. Flexible metal conduit in lengths not exceeding 4 ft can be used to connect physically adjustable equipment and devices within the fabricated duct.

Ex: Wiring methods and cables listed for plenum spaces can be installed in ducts specifically fabricated for environmental air handling purposes under the following conditions:

(1) The wiring method or cabling is necessary to connect to equipment or devices associated with the direct action upon or sensing of the contained air, and

(2) The total length of such wiring method or cabling doesn't exceed 4 ft.

Author's Comment:

Class 2 and Class 3 cables selected in accordance with Table 725.154 and installed in accordance with 725.135(B) are permitted to be installed in ducts specifically fabricated for environmental air [725.3(C) Ex. 1].

Power limited fire alarm cables selected in accordance with Table 760.154 and installed in accordance with 760.135(B) are permitted to be installed in ducts specifically fabricated for environmental air [760.3(B) Ex. 1].

Q3. What are the Code rules regarding wiring installed in plenum spaces such as above suspended ceilings or below a raised floor used for environmental air?

A3. Section 300.22(C) applies to spaces not specifically fabricated for environmental air-handling but used for air-handling as a plenum (space above a suspended ceiling or below a raised floor used for environmental air), it doesn't apply to habitable rooms or areas of buildings, the prime purpose of which isn't air handling.

Informational Note 1: The space or cavity above a suspended ceiling or below a raised floor used for environmental air are examples of the type of plenum space to which this section applies.

Ex: In a dwelling unit, this section doesn't apply to the space between joists or studs where the wiring passes through that space perpendicular to the long dimension of that space.

Wiring methods permitted in plenum spaces include electrical metallic tubing, rigid metal conduit, intermediate metal conduit, armored cable, metal clad cable without a nonmetallic cover, and flexible metal conduit. Surface metal raceways or metal wireways with metal covers can also be installed in a plenum space [300.22(C)(1)].

Cable ties for securing and supporting must be listed for use in a plenum space.

Author's Comment:

PVC conduit [Article 352], electrical nonmetallic tubing [Article 362], liquidtight flexible conduit, and nonmetallic cables aren't permitted to be installed in plenum spaces because they give off deadly toxic fumes when burned or superheated.

Plenum rated control, signaling, and communications cables and raceways are permitted in plenum spaces according to the following:

â–« Communications, 800.3(C), Table 800.154(a)

â–« Control and Signaling, 725.3(C) Ex 2, Table 725.154

â–« Coaxial Cable, 820.3(C), Table 820.154(a)

â–« Fire Alarm, 760.3(C) Ex 2, Table 760.154

â–« Optical Fiber Cables and Raceways, Table 770.154(a)

â–« Sound Systems, 640.9(C) and Table 725.154

Any wiring method suitable for the condition can be used in a space not used for environmental air handling purposes.

Metal cable tray systems can be installed to support the wiring methods and equipment permitted to be installed in a plenum space [300.22(C)(2)(a)].

(3) Equipment. Electrical equipment with a metal enclosure can be installed in a plenum space [300.22(C)(3)].

Author's Comment:

Examples of electrical equipment permitted in plenum spaces are air handlers, junction boxes, and dry type transformers; however, transformers must not be rated over 50 kVA when located in hollow spaces [450.13(B)].

Wiring methods beneath raised floors for information technology equipment can be installed as permitted in Article 645 [300.22(D)].

Q4. What are the NEC requirements when installing splices, taps, and feed-through conductors in a cabinet?

A4. A cabinet is an enclosure designed for surface or flush mounting that has a frame, mat or trim in which a swinging door or doors can be hung [Article 100]. Cabinets and cutout boxes are often used to enclose panelboards, switches, meters, current transformers, and control equipment. Cabinets are permitted to contain overcurrent protection devices and other wiring and equipment as provided in 312.8(A) and (B).

The wiring space within cabinets can be used for conductors feeding through, spliced, or tapping where all of the following conditions are met [312.8(A)]:

(1) The area of all conductors at any cross section doesn't exceed 40 percent of the cross sectional area of the space.

(2) The area of all conductors, splices, and taps installed at any cross section doesn't exceed 75 percent of the cross sectional area of that space.

(3) A permanently affixed warning label having sufficient durability to withstand the environment involved and comply with 110.21(B), must be applied on the cabinet to identify the location of the disconnecting means for the feed through conductors.

Q5. What NEC conditions must be met to install power monitoring equipment within cabinets?

A5. The wiring space within cabinets can contain power monitoring equipment where all of the following conditions are met [312.8(B)]:

(1) The power monitoring equipment is identified as a field installable accessory as part of listed equipment, or a listed kit for field installation in the overcurrent protection device enclosures.

(2) The area of all conductors, splices, taps, and equipment at any cross section doesn't exceed 75 percent of the cross sectional area of that space.

|