The Literally Shocking Truth About the Quality of Solar Arrays

By George Musser

For Scientific American

Photos courtesy of Corey Asbill

Feb 14, 2011

Solar panels are supposed to be a set-and-forget technology. Mine have performed just as advertised. All the installer said I need to do is look them over a couple of times a year and rinse off any dirt buildup. The approval and installation process had its delays and gaffes, but all’s well that ends well, I figure. But lately I’ve been feeling less sanguine. Solar experts have regaled me with tales of poor workmanship they find when they do spot checks of installed systems. As improperly installed joints corrode, connections loosen, and wires fray, we may be looking forward to a wave of breakdowns in the coming years. “Not only is there a potential for an increase in system failures, but there is also a potential for a rise in unsafe and potentially lethal situations,” says Corey Asbill of New Mexico State University.

Solar panels are supposed to be a set-and-forget technology. Mine have performed just as advertised. All the installer said I need to do is look them over a couple of times a year and rinse off any dirt buildup. The approval and installation process had its delays and gaffes, but all’s well that ends well, I figure. But lately I’ve been feeling less sanguine. Solar experts have regaled me with tales of poor workmanship they find when they do spot checks of installed systems. As improperly installed joints corrode, connections loosen, and wires fray, we may be looking forward to a wave of breakdowns in the coming years. “Not only is there a potential for an increase in system failures, but there is also a potential for a rise in unsafe and potentially lethal situations,” says Corey Asbill of New Mexico State University.

I brought up workmanship last week in the context of municipal codes, permits and inspections. Installers complain about the costly and seemingly arbitrary requirements that many cities, towns and counties impose. But the other side of the story is that local officials have the important responsibility of watching over installers. A couple of people slammed me in the comments field for letting bureaucrats off too easily and giving ammunition to solar’s detractors, but they neglected to address the reality of sloppy installations. A bad fire or lethal electrocution could zap public enthusiasm for photovoltaic power and jack up insurance premiums for all solar homeowners, even those whose installers did everything by the book.

Asbill is an electrical engineer, certified installer and member of a Department of Energy “Tiger Team” that goes around the country offering solar expertise. He tells me about a talk he gave in November 2009 to a meeting of installers and inspectors in Sonoma County, Calif. “It was a really nerve-racking talk, to be honest,” he says. His team had spent several days scrutinizing a sample of 15 nearby solar arrays and finding safety hazards in every one. “I was standing before this crowd and pointing out their mistakes,” he recalls. “I was nervous.”

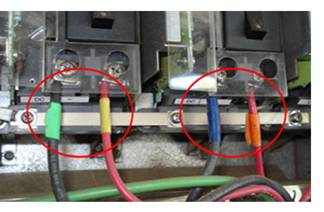

In an electrician’s version of Where’s Waldo, he put up photos of incorrectly installed equipment and asked the audience to spot what’s wrong. In the photo at the top of this post, for example, the red wires should be white. As code violations go, this one is fairly minor. A skilled electrician never trusts the color-coding, but lots of DIYers are not so savvy and might be led to assume a wire is hot, or not, based on its color.

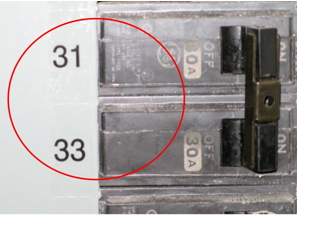

This double circuit breaker should have a warning label on it, indicating that the electricity is flowing into the service panel (from the solar array) rather than out (to an appliance or lamp). Again, a skilled electrician takes the right precautions regardless of what labels do or don’t say, but not everyone is so diligent.

This double circuit breaker should have a warning label on it, indicating that the electricity is flowing into the service panel (from the solar array) rather than out (to an appliance or lamp). Again, a skilled electrician takes the right precautions regardless of what labels do or don’t say, but not everyone is so diligent.

Here, the installer used a nonstandard part. Asbill speculates that the installers got out to the site only to realize they didn’t bring the right part, so they scrounged around in their toolbox for a substitute. The system works, for now, but will probably wear out prematurely.

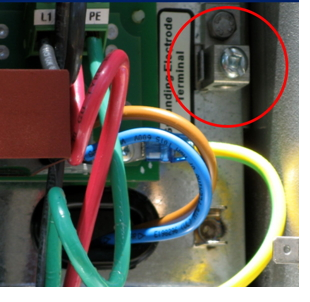

This one is more serious. The terminal at the upper right should have a ground wire in it. Grounding protects you if one of the live wires ever becomes frayed and makes contact with the metal box. Without it, someone touching the box could be electrocuted.

This one is more serious. The terminal at the upper right should have a ground wire in it. Grounding protects you if one of the live wires ever becomes frayed and makes contact with the metal box. Without it, someone touching the box could be electrocuted.

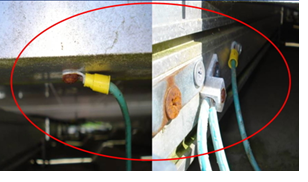

Look at these. The installer used grounding connectors meant for indoor use and they’re already corroded.

Look at these. The installer used grounding connectors meant for indoor use and they’re already corroded.

It doesn’t take an experienced inspector to see that a dangling conductor can’t be good, either.

It doesn’t take an experienced inspector to see that a dangling conductor can’t be good, either.

Now this is a real doozy. The installer never put in AC emergency cutoff switches! So there’s no easy way to shut off the equipment if someone needs to work on it.

Now this is a real doozy. The installer never put in AC emergency cutoff switches! So there’s no easy way to shut off the equipment if someone needs to work on it.

Despite Asbill’s initial nervousness, he says the audience took his critiques to heart. Sue Kateley, the executive director of the California Solar Energy Industries Association, raves about his presentation to this day. She has her own litany of complaints, such as a cracked electrical conduit that lets water in or is overstuffed with wires, causing mechanical wear. Greg Sellers, president of Burnham Energy, adds that many installers fail to check whether the general household wiring is up to snuff.

Asbill says he understands why installers cut corners and inspectors miss them. Both are overworked and undertrained. The solar industry is expanding so rapidly that education hasn’t kept up. Some states don’t even require electricians or roofers to get specialized training before they enter the solar trade.

Most installers guarantee their work for 10 years, but they don’t do regular check-ups. So I see a huge potential for after-sales service companies to step into the breach. Just as I get my boiler cleaned and checked each fall, I should get my panels examined annually to make sure everything is tight and nothing is hot. Such companies might also offer to upgrade panels when the technology improves enough to warrant it. Solar arrays may be rated for 25 years or longer, they won’t make it that long without some TLC.

This article, written by George Musser, appeared in Scientific American, a Division of Nature America, Inc.

Mike Holt’s recently released Understanding NEC Requirements for Solar Photovoltaic Systems covers all of these topics. Learn how to cross reference related code requirements to understand how they relate to one another, along with easy to understand explanations and graphics to aid in understanding difficult concepts, and how to make sure that installations are done safely and according to code.

Mike Holt’s recently released Understanding NEC Requirements for Solar Photovoltaic Systems covers all of these topics. Learn how to cross reference related code requirements to understand how they relate to one another, along with easy to understand explanations and graphics to aid in understanding difficult concepts, and how to make sure that installations are done safely and according to code.

For more information visit www.mikeholt.com/solar