|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Figure 01

|

|

|

Figure 01

|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Note: The answers to these questions are based on the 2020 NEC.

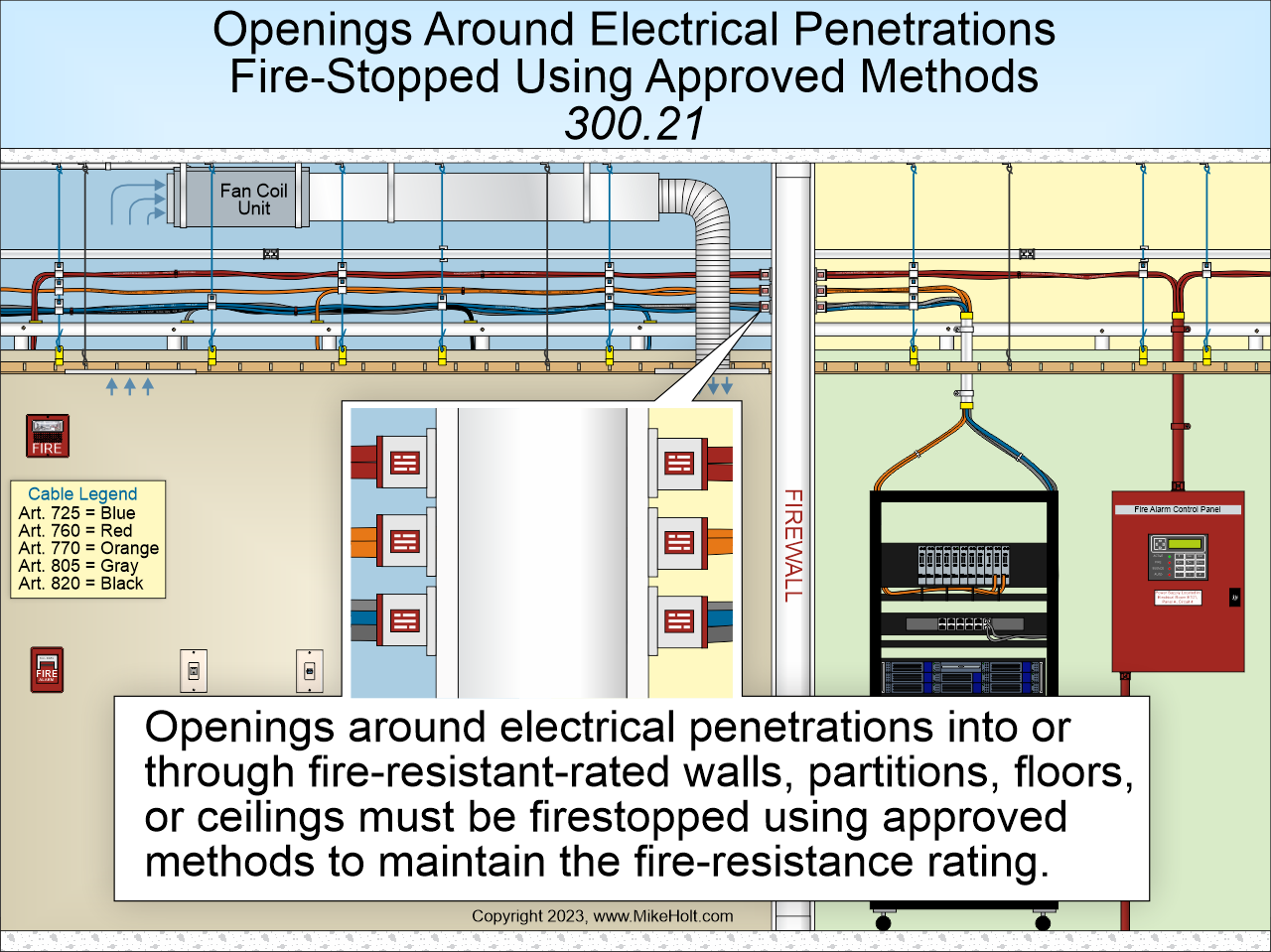

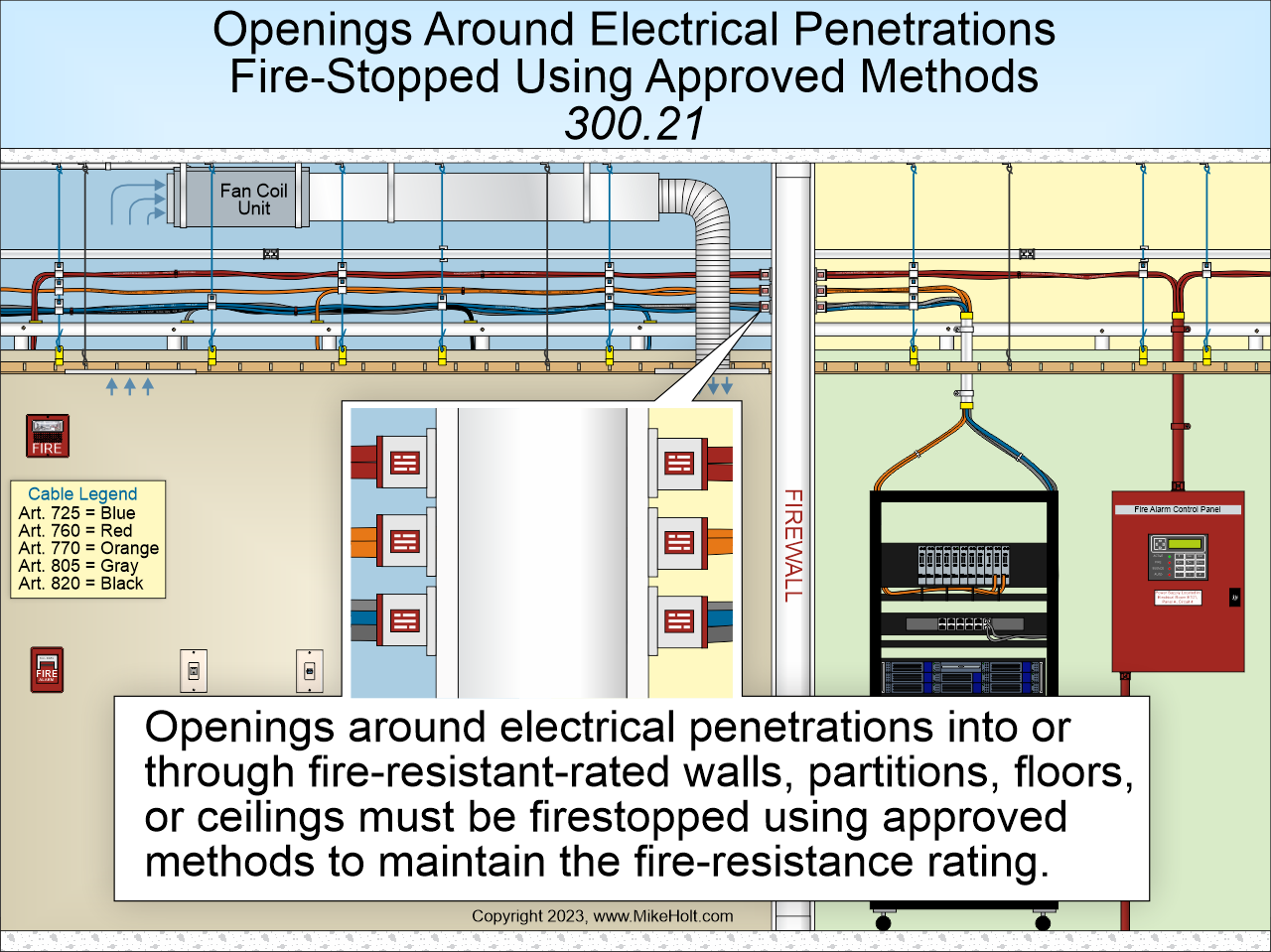

Q1. What are the basic rules related to electrical circuits and equipment installed to reduce the spread of fire or products of combustion?

300.21 Spread of Fire or Products of Combustion. Electrical circuits and equipment must be installed in such a way that the spread of fire or products of combustion will not be substantially increased. Openings around electrical penetrations into or through fire-resistant-rated walls, partitions, floors, or ceilings must be firestopped using approved methods to maintain the fire-resistance rating.‚Figure 01

Note: Directories of electrical construction materials published by recognized testing laboratories contain listing and installation restrictions necessary to maintain the fire-resistive rating of assemblies. Building codes also have restrictions on penetrations on opposite sides of a fire-resistance-rated wall. Outlet boxes must have a horizontal separation of not less than 24 in. when installed on opposite sides in a fire-rated assembly, unless an outlet box is listed for closer spacing or protected by fire-resistant putty pads in accordance with the manufacturer's instructions.

Author's Comment:

â–ºBoxes installed in fire-resistance-rated assemblies must be listed for the purpose. If steel boxes are used, they must be secured to the framing member. Cut-in type boxes are not permitted.

►Building code requirements restrict penetrations on a fire-rated assembly section of 100 sq ft to 100 sq in. of allowable penetrations, therefore if a 4 × 4 metal box has 16 sq in., then only six boxes (100/16 = 6.25) are allowed in that section of fire wall in accordance with IBC 714.4.2, International Building Code.

â–ºThis requirement also applies to:

â–ºClass 2 Power-Limited Circuits, 725.3(B)

â–ºCoaxial Cable, 800.26

â–ºFire Alarms, 760.3(A)

â–ºOptical Fiber Cable, 770.26

Q.2 What are the NEC requirements related to the installation if wiring within ducts for dust, vapor, or environmental air?

300.22 Wiring in Ducts. The requirements of this section apply to the installation and uses of electrical wiring and equipment in ducts used for dust or vapor removal, ducts specifically fabricated for environmental air.

(A) Ducts Used for Dust or Vapor. Wiring methods are not permitted to be installed in ducts that transport dust or flammable vapors.

(B) Ducts Fabricated for Environmental Air. Equipment and wiring methods are only permitted within a duct fabricated to transport environmental air if the equipment is necessary for the direct action upon, or sensing of, the contained air.‚

Type MC cable without an overall nonmetallic covering and metal raceways can be installed in ducts fabricated to transport environmental air. Flexible metal conduit in lengths not exceeding 4 ft can be used to connect physically adjustable equipment and devices within the fabricated duct.

Ex: Wiring methods and cabling systems, listed for use in plenum spaces, can be installed in ducts specifically fabricated for environmental air-handling purposes under both of the following conditions:

(1) The wiring methods or cabling systems are necessary to connect to equipment or devices associated with the direct action upon or sensing of the contained air, and

(2) The total length of such wiring methods or cabling systems does not exceed 4 ft.

Q3. What are the NEC requirements related to the installation if wiring within plenum spaces for environmental air?

300.22 Wiring in Ducts. The requirements of this section apply to the installation and uses of electrical wiring and equipment in plenum spaces for environmental air.

(C) Plenum Spaces for Environmental Air. This section applies only to the space above a suspended ceiling or below a raised floor used for environmental air. It does not apply to habitable rooms or areas of buildings, the prime purpose of which is not air handling.

Note 1: The spaces or cavities above a suspended ceiling and below a raised floor used for environmental air are examples of the type of plenum spaces to which this section applies.‚

(1) Wiring Methods. Metal raceways, Type AC cable, and Type MC cable without a nonmetallic cover, electrical metallic tubing, intermediate metal conduit, rigid metal conduit, flexible metal conduit, or (where accessible) surface metal raceways or metal wireways with metal covers are permitted to be installed in the plenum space.

Cable ties for securing and supporting cables must be listed for use in a plenum space.

Author's Comment:

â–ºPlenum-rated Chapter 7 and Chapter 8 wiring methods are permitted in plenum spaces according to the following:

â–ºClass 2 Power-Limited Cables, 725.3(B)

â–ºCoaxial Cables, 800.3(C)

â–ºFire Alarm Cables, 760.3(B) Ex 2

(2) Cable Tray Systems.

(a) Metal Cable Tray Systems. Metal cable tray systems can be installed to support the wiring methods permitted to be installed in a plenum space.

(3) Equipment. Electrical equipment with a metal enclosure or a nonmetallic enclosure listed for use in an air-handling space can be installed in a plenum space.

Author's Comment:

â–ºExamples of electrical equipment permitted in plenum spaces are air handlers, junction boxes, and dry-type transformers although transformers are not permitted to be rated over 50 kVA when in hollow spaces [450.13(B)].

|