|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

Using Class 2 circuits may eliminate shock or fire hazards, but only if you install them correctly.

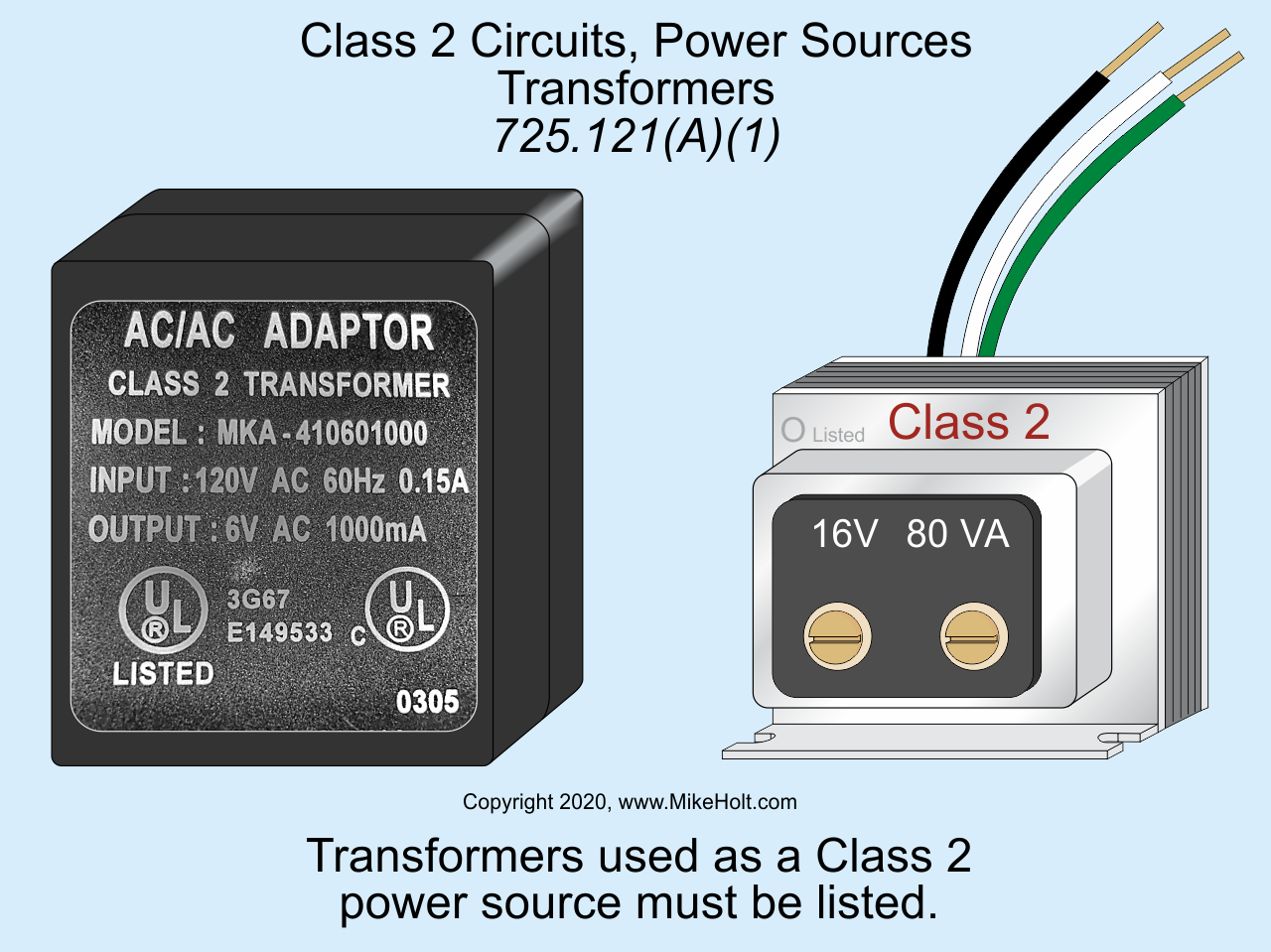

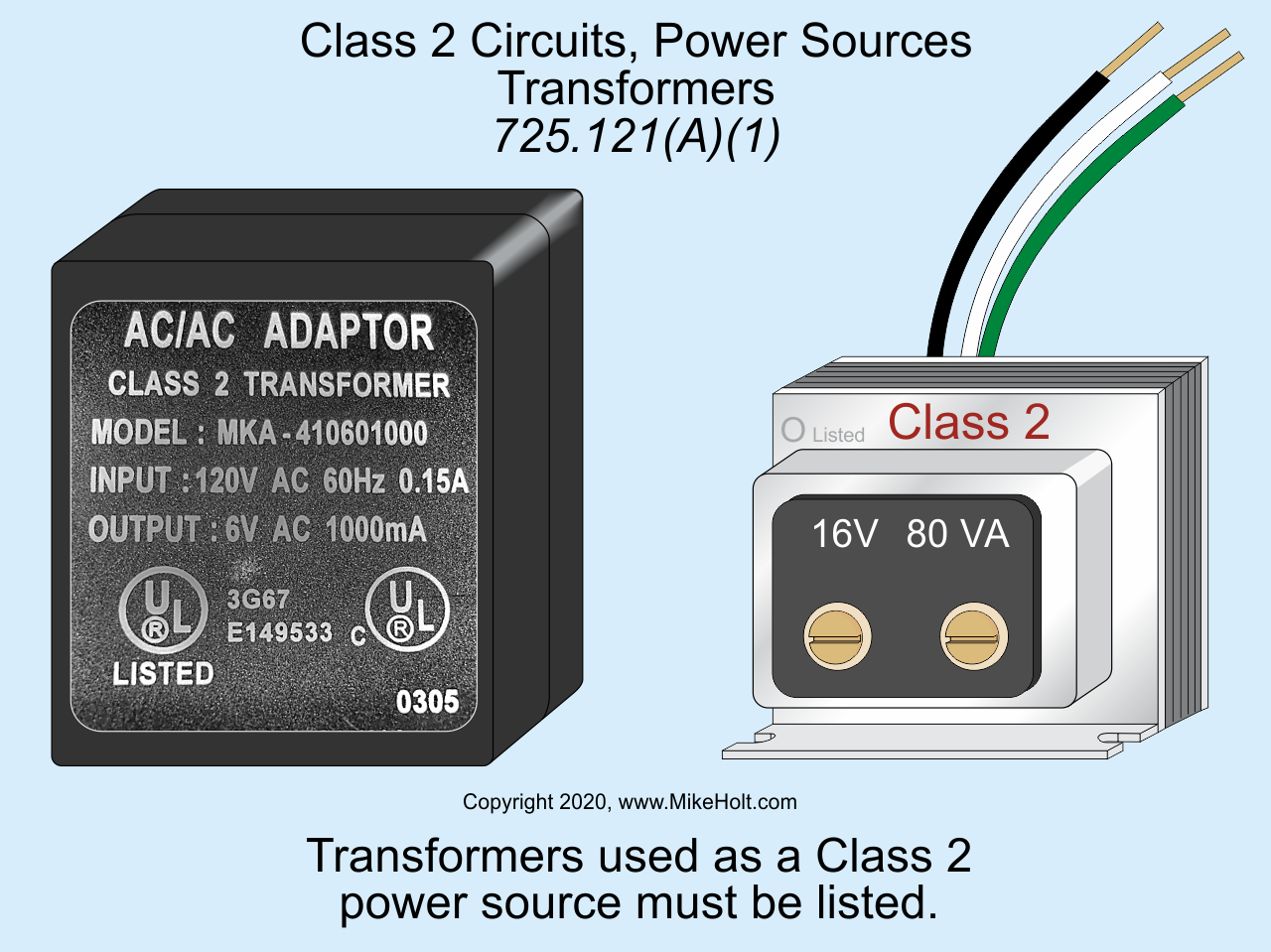

Figure 01

|

|

|

Figure 01

|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

Using Class 2 circuits may eliminate shock or fire hazards, but only if you install them correctly.

Class 2 circuits are limited to voltage and current values that don't (usually) present a shock or fire hazard.

The power supply for a Class 2 circuit must be as follows [725.121(A)]:

(1) A listed Class 2 transformer. Figure 01

(2) A listed Class 2 power supply.

(3) Equipment listed as a Class 2 power source.

Ex 2: Where a circuit has an energy level at or below the limits in Chapter 9, Table 11(A) and 11(B), the equipment need not be listed as Class 2.

(4) Listed audio/video information technology equipment, communications, and industrial equipment limited-power circuits

A fifth power supply available to Class 2 circuits is a battery source / system that is listed and identified as Class 2.

Class 2 cables

For corrosive, damp, or wet locations, Class 2 cables must be identified for the location per 110.11 and 310.10(F). Conductors and cables in underground raceways [300.5(B)], or in raceways aboveground in wet locations [300.9], must also be identified for wet locations. Where corrosion may occur, follow the requirements of 300.6 [725.3(L)].

Class 2 cables can be installed in:

- Cable routing assemblies selected per Table 800.154(c), listed per 800.182, and installed per 800.110(C) and 800.113 [725.3(M)]

- Communications raceways selected per Table 800.154(b), listed per 800.182, and installed per 800.113 and 362.24 through 362.56, where the requirements applicable to electrical nonmetallic tubing apply [725.3(N)].

The requirements of 310.14(A)(3) for the temperature limitation of conductors apply to Class 2 cables [725.3(O)]. The accessible portion of Class 2 cables not terminated at equipment or tagged for future use must be removed [725.25].

Marking

The power sources for power-limited circuits in 725.121(A)(3) and power-limited circuits for listed audio/video equipment, listed information technology equipment, listed communications equipment, and listed industrial equipment in 725.121(A)(4) must be labeled with the maximum voltage and rated current output per conductor for each connection point on the power source [725.121(C)].

Equipment supplying Class 2 circuits must be durably marked to indicate each circuit that is Class 2 [725.124].

Wiring methods

Conductors and equipment on the supply side of the Class 2 power supply must be installed per Chapters 1 through 4. The overcurrent protection for Class 2 transformers or power supplies must not exceed 20A [725.127].

Class 2 circuits can use a Class 1 wiring method per 725.46 [725.130(A)]. Class 2 circuits can be reclassified as a Class 1 circuit if the Class 2 equipment markings are eliminated and the circuit is installed using a Chapter 3 wiring method per 725.46 [725.130(A) Ex 2].

Where a Class 2 circuit is reclassified as a Class 1 circuit, it can be run in the same raceway, cable, or enclosure with power conductors of functionally associated equipment [725.48(B)]. Class 2 circuits reclassified and installed as Class 1 circuits are no longer Class 2 circuits, regardless of their continued connection to a Class 2 power source [725.130(A) Note].

Class 2 circuits can use Class 2 wiring of the type in 725.179 if installed per 725.133 and 725.154 [725.130(B)].

Cable installation

Class 2 cable installation must comply with 725.135(A) through (M). For example:

- Plenum rated Class 2 cables can be installed within plenum air spaces per 725.3(C) Ex 2 if the Class 2 cables are plenum rated, except were installed in a metallic raceway per 300.22(C) [725.135(C)].

- Cables installed in cable trays outdoors must be Type PLTC.

You'll see some overlap, also. For example, the following cables are permitted in cable trays inside buildings 725.135(H) and in dwelling units [725.135(M)]: PLTC cables and types CL2P, CL3P, CL2R, CL3R, CL2, and CL3.

Separation

Class 2 cables are not permitted in any enclosure or raceway with power and Class 1 circuits, except as permitted in 725.136(B) through (I).

For example, Class 2 circuit conductors can be installed with power conductors and Class 1 conductors if separated by a barrier [725.136(B)].

You can mix conductors of different circuits, per 725.139(A) through (F). For example, Class 2 circuit conductors can be in the same:

- Cable, cable routing assembly, enclosure, or raceway with other Class 2 circuit conductors [725.139(A)].

- Cable with conductors of communications circuits if the cable is a listed communications cable that has been installed per Part V of Article 805 [725.139(D)].

Power and data transmission

Section 300.11 and Parts I and III of Article 725 apply to Class 2 circuits that transmit power and data. Conductors that carry power and data must be copper and the current cannot exceed the current limitation of the connectors [725.144]. Six informational notes follow 725.144 (and these have been heavily revised with the 2020 cycle). For example:

- Note 1: Closed-circuit TV camera (CCTV) circuits are example of cables that transmit power and data.

- Note 6: The rated current for power sources covered in 725.144 is the output current per conductor the power source is designed to deliver to an operational load at normal operating conditions, as declared by the manufacturer. In the design of these systems, the actual current in a given conductor might vary from the rated current per conductor by as much as 20 percent. An increase in current in one conductor is offset by a corresponding decrease in current in one or more conductors of the same cable.

Table 725.144 is an ampacity table for 4-pair Class 2 power/data cables. Make sure you understand the notes that come with it. For example, where only half of the conductors in each cable are carrying current, you can increase the values in the table by a factor of 1.40 [Table 725.144 Note 2].

Compliance with Table 725.144 is not required for conductors 24 AWG or larger where the rated current per conductor of the power source does not exceed 0.30A.

One example of the use of Class 2 cables is a network of closed-circuit TV cameras using 24 AWG, 60°C rated, Type CL2R, Category 5e balanced twisted-pair cabling.

Cable Types CL3P-LP, CL2P-LP, CL3R-LP, CL2R-LP, CL3-LP, or CL2-LP can supply power to equipment from a power source with a rated current per conductor up to the marked current limit located immediately following the suffix -LP and can transmit data to the equipment [725.144(B)].

Where the number of bundled LP cables is 192 or less and the selected ampacity of the cables per Table 725.144 exceeds the marked current limit of the cable, you can determine the ampacity from the table. For ambient temperatures above 30°C, you must apply the correction factors of Table 310.15(B)(1) or Equation 310.15(B)(2).

The Class 2-LP cables must comply with the following, as applicable:

(1) Cables with the suffix -LP can be installed in bundles, raceways, cable trays, communications raceways, and cable routing assemblies.

(2) Cables with the suffix -LP and a marked current limit must follow the substitution hierarchy of Table 725.154 and Figure 725.154(A) in the NEC for the cable type without the suffix -LP and without the marked current limit.

(3) System design is permitted by qualified persons under engineering supervision.

An example of a limited power (LP) cable is a cable marked Type CL2-LP (0.5A), 23 AWG.

Class 2 cables must comply with 725.154(A) through (C) and Table 725.154.

For example, cable substitutions can be made per Table 725.154(A) and Figure 725.154(A) Cable Substitution Hierarchy.

There is no Table 725.154(B), but preceding Table 725.154(A) (as you move through Article 725 from front to back) is Table 725.154. This table shows you which of ten cable types you can use for a given application. For example, in a riser vertical run you can use CL2P, CL3P, CL2R, and CL3R, but not CL2, CL3, CL2X,CL3X, CMUC, or PLTC.

Avoiding Class 2 errors

The supply side equipment and wiring of Class 2 circuits fall under Chapters 1 through 4, not under Article 725. On the load side, you need to follow Article 725 requirements. Remember that Class 2 circuits are limited so as to prevent shock or fire. That means you separate them from circuits that are not so limited. You also must use the cable type that is appropriate for the application.

If you have Class 1, Class 2, and Class 3 remote control and signaling circuits in the same facility, mark these at each panel and junction box both on the drawings and physically so they don't get mixed together.

Learn more with Mike's Understanding the NEC Complete Library:

|