|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Figure 01

|

|

|

Figure 01

|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Note: The answers to these questions are based on the 2020 NEC.

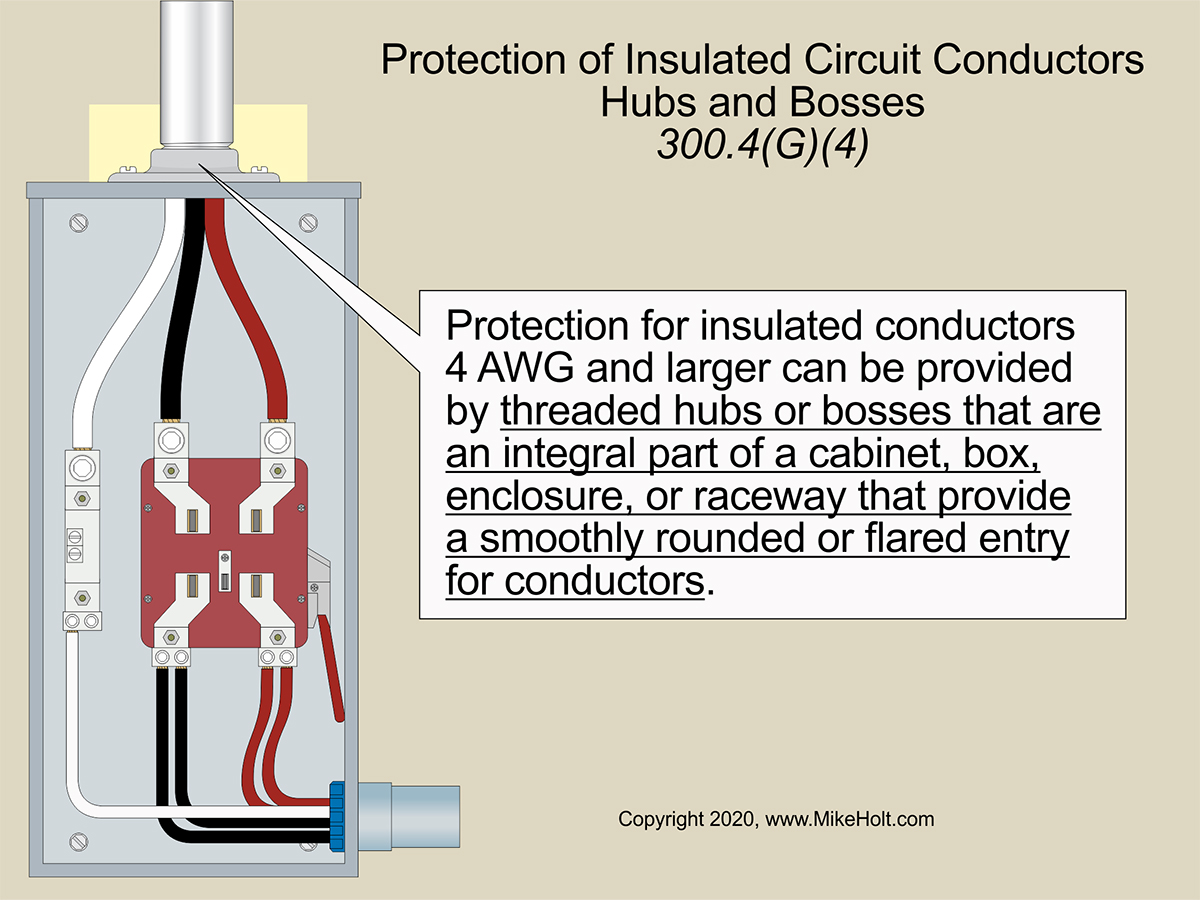

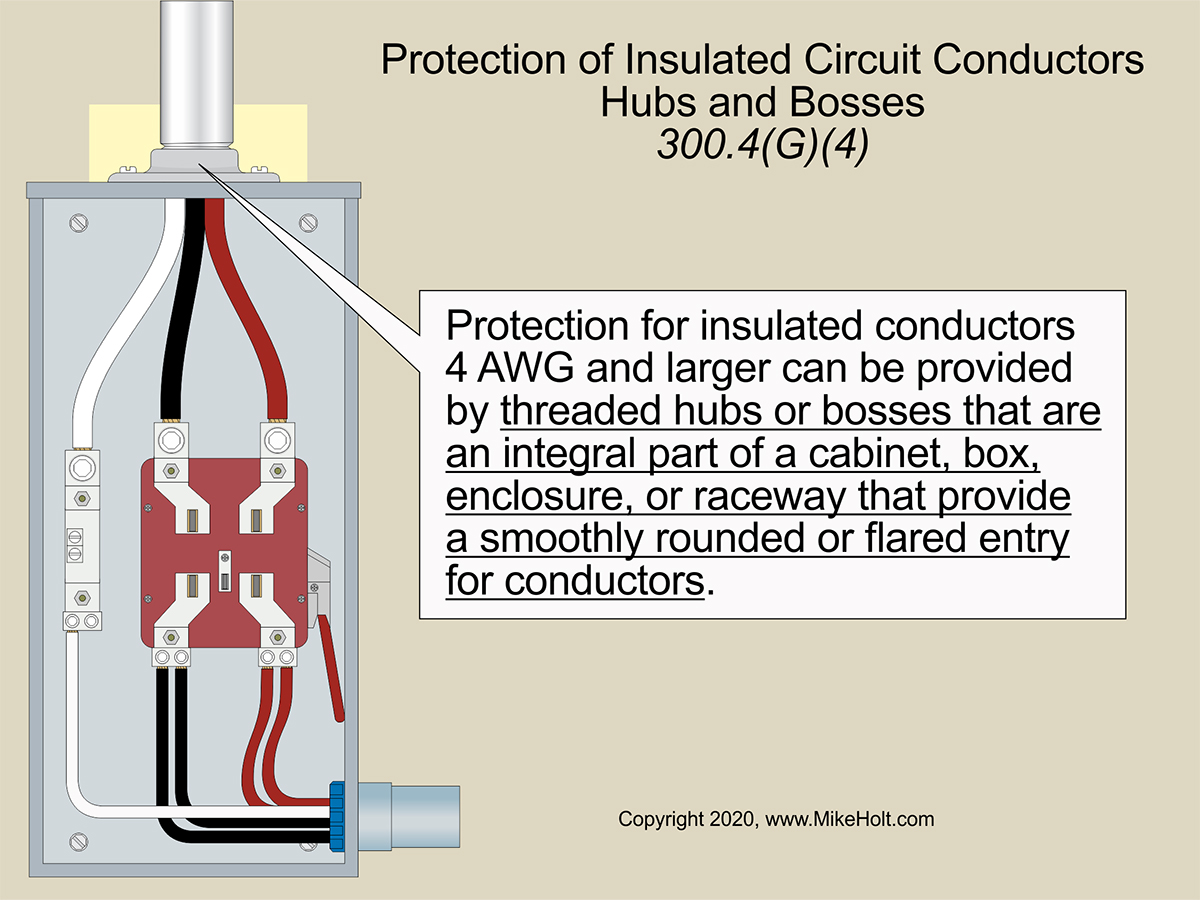

Q1. What does the Code require when conductors 4 AWG and larger enter a cabinet, box, enclosure, or raceway?

A1. Where subject to physical damage, conductors, raceways, and cables must be protected in accordance with (A) through (H) [300.4].

(G) Fittings. Raceways containing insulated circuit conductors 4 AWG and larger that enter a cabinet, box, enclosure, or raceway, must have the conductors protected as follows:

(1) A fitting providing a smoothly rounded insulating surface

(2) A listed metal fitting that has smoothly rounded edges.

(3) Separation from the fitting or raceway using an identified insulating material that is securely fastened in place

(4) Threaded hubs or bosses that are an integral part of a cabinet, box, enclosure, or raceway that provide a smoothly rounded or flared entry for conductors. Figure 01

Q2. What does the Code require when a raceway is subjected to different temperatures and condensations is known to be a problem?

A2. (A) Sealing. If a raceway is subjected to different temperatures, and where condensation is known to be a problem, the raceway must be filled with a material approved by the authority having jurisdiction that will prevent the circulation of warm air to a colder section of the raceway. Sealants must be identified for use with cable insulation, conductor insulation, a bare conductor, a shield, or other components. Special sealing fittings such as an explosionproof seal is not required [300.7(A)].‚

Author's Comment:

►One common product used for this is electrical duct seal and it is so identified. There are other identified products such as Polywater's FST Duct Sealant. Typical expanding foams used to seal buildings are not identified for this application.

Q3. What is the NEC rule about wiring installed in exit enclosures (stair towers)?

A3. 300.25 Exit Enclosures (Stair Towers)

Where an exit enclosure is required to be separated from the building, only electrical wiring methods serving equipment permitted by the authority having jurisdiction in the exit enclosure are permitted to be installed within the exit enclosure.

Author's Comment:

As used here, separated from the building does not necessarily mean detached. Article 100 defines a ˜building' as a structure that stands alone or that is separated from adjoining structures by fire walls. The fire rating rules for walls surrounding a star tower are much more stringent and serve to ˜separate' it from the main building. The intent of this requirement is to limit the materials within an exit enclosure to only those needed to serve the intended function of the exit enclosure for a safe passage out of the building in the event of an emergency, such as egress lighting. If the need should arise that a stair tower landing was the only place for a sub-panel, (for example), to be installed, it would require documented special permission from the authority having jurisdiction.

Informational Note: For more information, refer to NFPA 101, Life Safety Code, 7.1.3.2(10)(b).

Q4. What is the maximum voltage rating for conductors covered in Article 310 of the NEC?

A4. Article 310 contains the general requirements for conductors rated up to and including 2,000V, such as insulation markings, ampacity ratings, and their use [310.1].

Informational Note: For flexible cords and cable, see Article 400. For fixture wires, see Article 402.

Q5. What are the Code rules for sizing of service and feeder conductors supplying a single dwelling?

A5. Dwelling unit service and feeder conductors supplied by a single-phase, 120/240V systems can be sized in accordance with 310.12(A) through (D) and dwelling unit single-phase feeder conductors supplied by a three-phase 120/208V wye system can be sized in accordance with 310.12(A) through (C):

(A) Services rated 100A through 400A. Single-phase 120/240V service conductors supplying the entire load associated with the dwelling unit can have the conductor sized in accordance with Table 310.12 where there is no conductor ampacity adjustment or correction as required by 310.14.

Example

Question: What size service conductors are required if the calculated load for a dwelling unit requires a service disconnect rated 200A?

(a) 1/0 AWG (b) 2/0 AWG (c) 3/0 AWG (d) 4/0 AWG

Answer: (b) 2/0 AWG [Table 310.12]

Author's Comment:

►Section 310.12 cannot be used for service conductors for two-family or multifamily dwelling buildings.

(B) Feeders rated 100A through 400A. Single-phase 120/240V or 120/208V feeder conductors supplying the entire load associated with the dwelling unit can have the conductor sized in accordance with Table 310.12 where there is no conductor ampacity adjustment or correction as required by 310.14.

Example

Question: What size feeder conductors are required if the calculated load for a dwelling unit requires a service disconnect rated 200A, and the feeder conductors carry the entire load of the dwelling unit?‚

(a) 1/0 AWG (b) 2/0 AWG (c) 3/0 AWG (d) 4/0 AWG

Answer: (b) 2/0 AWG [Table 310.12]

Author's Comment:

►Table 310.12 cannot be used to size feeder conductors where a feeder does not carry the entire load of the dwelling unit, except as permitted in 310.12(C).

(C) Feeder Conductors Not Greater Than Service Conductors. Feeder conductors for an individual dwelling unit are not required to be sized larger than the service conductors sized to Table 310.12.

(D) Neutral Conductors. Neutral conductors are permitted to be sized smaller than the phase conductors if the requirements of 220.61(A) and 230.42 for service conductors and the requirements of 215.2 and 220.61(A) for feeder conductors are met.

|