|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

Separately derived systems have special grounding and bonding requirements.

Figure 01

|

|

|

Figure 01

|

By Mike Holt

NEC® Consultant for EC&M Magazine

Note: This article is based on the 2020 NEC.

Separately derived systems have special grounding and bonding requirements.

What is a separately derived system (SDS)? Its defining characteristic is it's not connected to the current-carrying conductors of another electrical source.

The NEC defines it as an electrical source (other than a service) that has no direct connection to circuit conductors of any other electrical source other than those established by grounding and bonding connections [Article 100]. A power transformer or an onsite generator may be installed as an SDS.

SDS grounding

You must run a grounding electrode conductor to one or more grounding electrodes per 250.50 and 250.30(C) from the same location where the system bonding jumper has been installed [250.30(A)(4)]. Size it per 250.66, based on the area of the largest secondary phase conductor [250.30(A)(5)].

If the SDS is indoors, you must install the required system bonding jumper at the secondary neutral terminal of the SDS or at the first system disconnect [250.30(A)(1)(a)], and size it per Table 250.102(C)(1) based on the area of the secondary phase conductor.

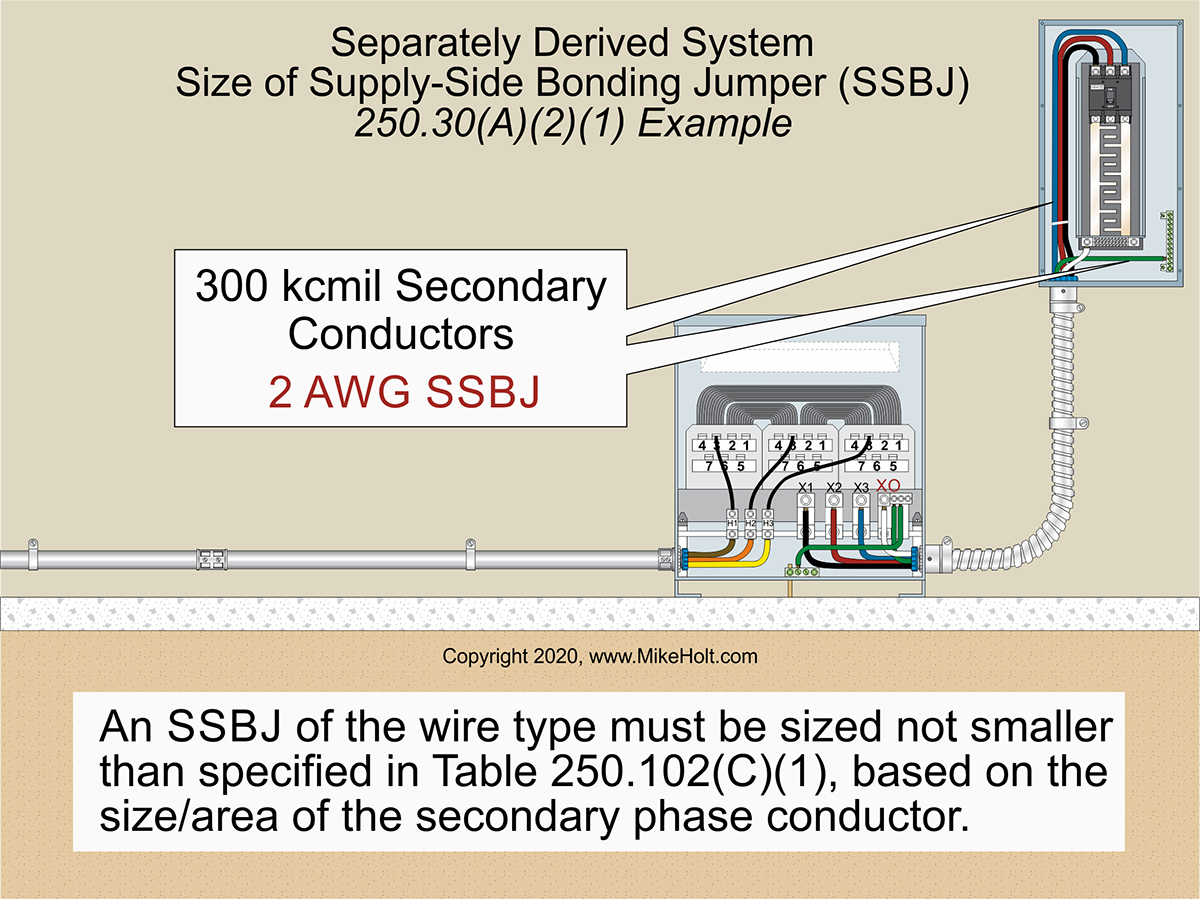

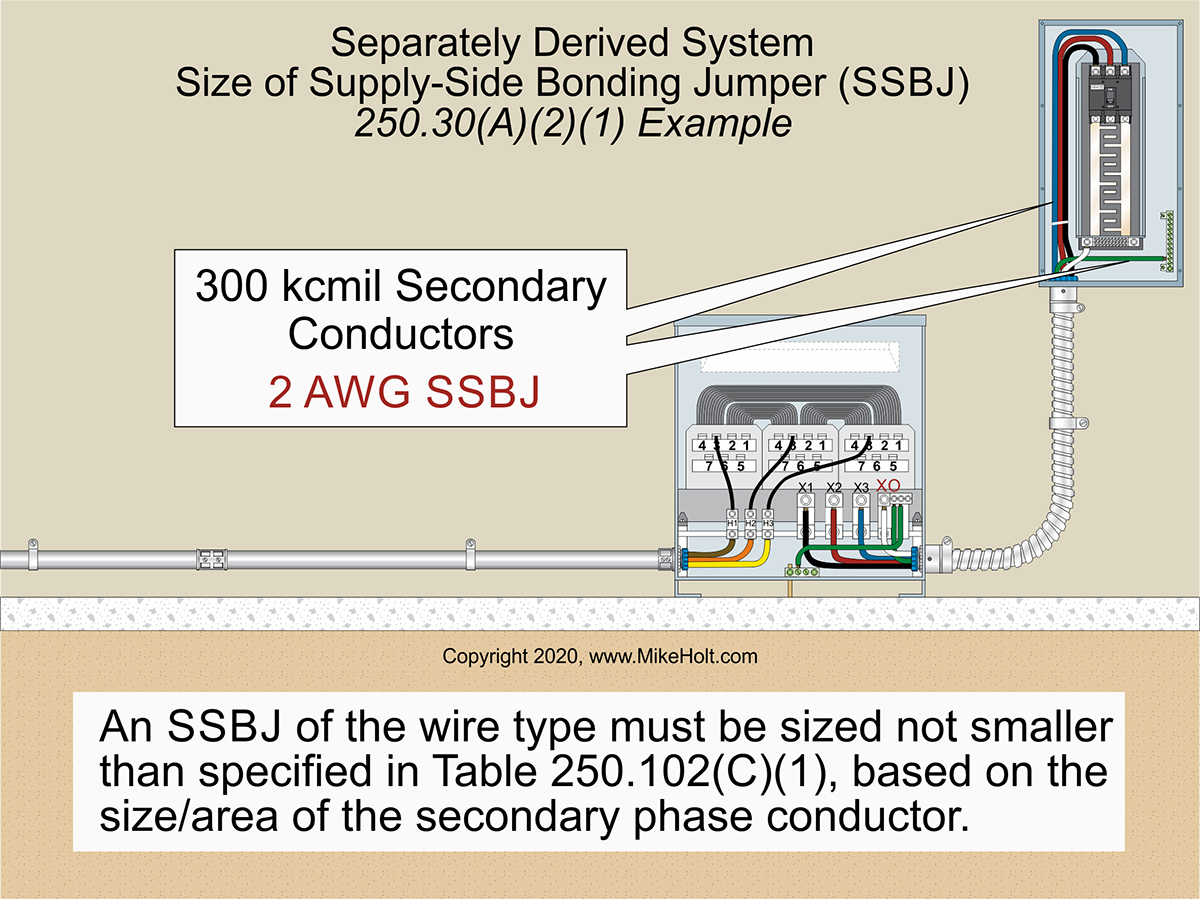

SDS Supply Side Bonding Jumper

You must run a supply-side bonding jumper from the SDS equipment grounding conductor terminal to the equipment grounding conductor terminal on the secondary system disconnect enclosure and size it per Table 250.102(C)(1) based on the area of the secondary phase conductor [250.30(A)(2)(1)].

Example question: What size supply-side bonding jumper is required for flexible metal conduit containing 300 kcmil secondary conductors? Figure 01

(a) 4 AWG (b) 2 AWG (c) 1/0 AWG (d) 3/0 AWG

Answer: (b) 2 AWG [Table 250.102(C)(1)]

When the system bonding jumper is installed at a secondary system disconnect, a secondary neutral conductor in each raceway, sized no smaller than specified in Table 250.102(C)(1), must be run from the SDS secondary to the disconnect enclosure of the secondary system.

Example question: What size neutral conductor is required for a 112.50 kVA transformer paralleled in two raceways with 3/0 AWG secondary conductors in each raceway?

(a) 3 AWG (b) 2 AWG (c) 1 AWG (d) 1/0 AWG

Answer: (d) 1/0 AWG [Table 250.102(C)(1)]

Table 250.102(C)(1) requires a minimum of a 2 AWG neutral conductor based on the equivalent size of two 3/0 AWG conductors (167,800 cmil × 2 conductors = 335,600 cmil), but the minimum size neutral conductor in parallel is 1/0 AWG [310.10(G)(1)].

Ensure the 1/0 AWG conductor is large enough to handle the maximum unbalanced load [220.61]. When a system bonding jumper is installed at the secondary system disconnect, the secondary neutral conductor will serve as part of the effective ground-fault current path.

SDS supplied building

If overcurrent protection is provided at the SDS, the installation must contain an equipment grounding conductor per 250.32(B)(1) [250.32(B)(a)]. If overcurrent protection is not provided at the SDS, the installation must comply with 250.30(A). [250.32(B)(2)(b)].

Grounding electrode conductor size

The grounding electrode conductor at a separate building must terminate to the equipment grounding terminal of the disconnect (not the neutral terminal). Size it per 250.66 based on the area of the largest phase conductor [250.32(E)].

Example question: What size grounding electrode conductor is required for a building disconnect supplied with a 3/0 AWG feeder with a concrete-encased electrode?

(a) 4 AWG (b) 2 AWG (c) 1 AWG (d) 1/0 AWG

Answer: (a) 4 AWG [250.66(B) and Table 250.66]

If the grounding electrode conductor is connected to a rod(s), the portion of the conductor that connects only to the rod(s) is not required to be larger than 6 AWG copper [250.66(A)]. If the grounding electrode conductor is connected to a concrete-encased electrode(s), the portion of the conductor that connects only to the concrete-encased electrode(s) is not required to be larger than 4 AWG copper [250.66(B)].

Non-stationary generators

A portable generator is not required to connect to a grounding electrode (grounded) where all the following conditions are met [250.34(A)]:

(1) The generator supplies only equipment and/or receptacles mounted on the generator.

(2) The normally noncurrent-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are connected to the generator frame.

A vehicle- or trailer-mounted generator is not required to be connected to a grounding electrode where all the following conditions are met [250.34(B)]:

(1) The generator frame is bonded to the vehicle or trailer frame.

(2) The generator supplies only equipment or receptacles mounted on the vehicle, trailer, or generator.

(3) The normally noncurrent-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are connected to the generator frame.

High-impedance ground

High-impedance grounded three-phase systems of 480V up to 1,000V are permitted where all the following conditions are met [250.36]:

(1) Conditions of maintenance and supervision ensure only qualified persons service the installation.

(2) The system has ground detectors.

(3) Only line-to-line loads are served.

To minimize fault current, high-impedance grounded systems usually have a resistor installed between the neutral point of the SDS and the grounding electrode conductor.

Error-free grounding and bonding on electrical power sources

To avoid grounding and bonding errors on electrical power sources such as transformers and generators, first determine whether the unit you are installing is an SDS. If it is not, you bond it and do not ground it. If it is an SDS, you must ground it per the requirements that begin in 250.30.

|