|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Figure 01

|

|

|

Figure 01

|

For EC&M Magazine

By Mike Holt, NEC® Consultant

Here's the follow-up to yesterday's newsletter.

This includes the answers to the questions sent, so you can see how you did.

Note: The answers to these questions are based on the 2017 NEC.

Q1. What is the NEC definition of a motor controller?

A1. Controller. A switch or device used to start and stop a motor by making and breaking the motor circuit current [430.2].

Author's Comment:

• A controller can be a horsepower-rated switch, snap switch, or circuit breaker. A pushbutton that operates an electromechanical relay isn't a controller because it doesn't meet the controller rating requirements of 430.83. Devices such as start-stop stations and pressure switches are control devices, not motor controllers.

• The controllers discussed in Article 430 are those that meet this definition, not the definition of Controller in Article 100.

Q2. Where is the motor current found for use in sizing the various components of a motor circuit?

A2. (A) General Requirements [430.6(A)].

(1) Table Full-Load Current (FLC). The motor full-load current ratings listed in Tables 430.247, 430.248, and 430.250 are used to determine the conductor ampacity [430.22], the branch-circuit short-circuit and ground-fault overcurrent protection device size [430.52 and 430.62], and the ampere rating of disconnecting switches [430.110].

Author's Comment:

• The actual current rating on the motor nameplate full-load amperes (FLA) [430.6(A)(2)] isn't permitted to be used to determine the conductor ampacity, the branch-circuit short-circuit and ground-fault overcurrent protection device size, nor the ampere rating of disconnecting switches.

Motors built to operate at less than 1,200 RPM or that have high torques may have higher full-load currents, and multispeed motors have full-load current varying with speed, in which case the nameplate current ratings must be used [430.6(A)(1)].

Ex 3: For a listed motor-operated appliance, the actual current marked on the nameplate of the appliance must be used instead of the horsepower rating on the appliance nameplate to determine the ampacity or rating of the disconnect, the branch-circuit conductors, the controller, and the branch-circuit short-circuit and ground-fault protection.

(2) Motor Nameplate Current Rating (FLA). Overload devices must be sized based on the motor nameplate current rating in accordance with 430.31.

Author's Comment:

• The motor nameplate full-load ampere rating is identified as full-load amperes (FLA). The FLA rating is the current in amperes the motor draws while producing its rated horsepower load at its rated voltage, based on its rated efficiency and power factor.

• The actual current drawn by the motor depends upon the load on the motor and on the actual operating voltage at the motor terminals. That is, if the load increases, the current also increases, or if the motor operates at a voltage below its nameplate rating, the operating current will increase.

CAUTION: To prevent damage to motor windings from excessive heat (caused by excessive current), never load a motor above its horsepower rating, and be sure the voltage source matches the motor's voltage rating.

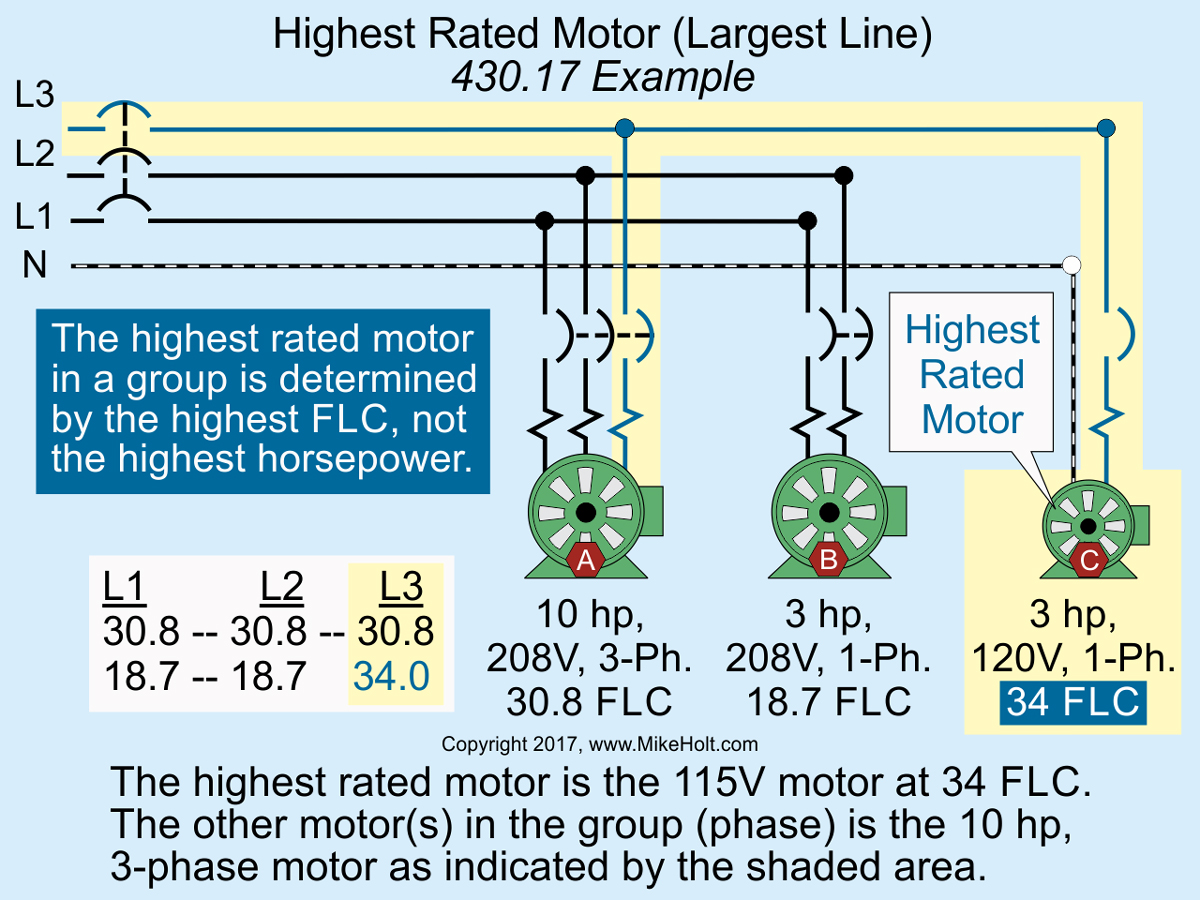

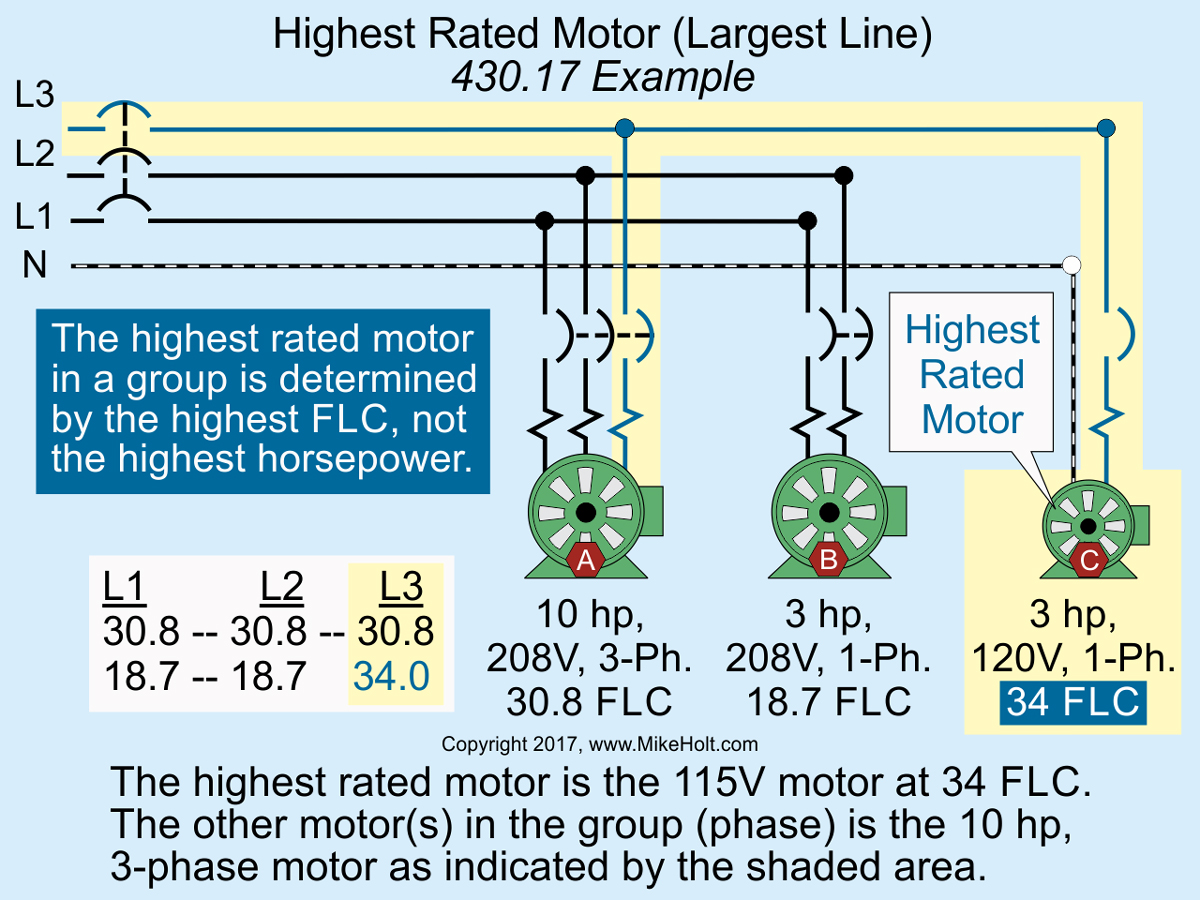

Q3. When the NEC refers to the highest rated motor on a circuit with multiple motors, how is the largest motor of the group determined?

A3. When sizing motor circuit conductors, the highest rated motor is the motor with the highest rated full-load current rating (FLC) [430.17].

Example: Which of the following motors has the highest FLC rating?

A good method to determine the highest rated motor is to draw out the motor circuit as follows:Figure 01

10 hp = 30.80A [Table 430.250]

5 hp = 30.80A [Table 430.248]

3 hp = 34.00A [Table 430.248]

Answer: The 3 hp, single-phase, 120V motor has the highest FLC rating.

Q4. What is the Code required method of sizing the conductors to a single continuous duty motor?

A4. Conductors to a single motor must be sized not less than 125 percent of the motor FLC rating as listed in Table 430.247 Direct-Current Motors, Table 430.248 Single-Phase Motors, or Table 430.250 Three-Phase Motors [430.22].

Example: What size circuit conductor is required for a 3 hp, 230V, single-phase motor?

Solution:

Determine the branch-circuit conductor size based on the motor's FLC [430.6(A)(1), 430.22(A), and Table 310.15(B)(16)].

3 hp, 230V Motor FLC = 17A [Table 430.248]

17A × 1.25 = 21.25A

Answer: 10 AWG rated 30A at 60°C [Table 310.15(B)(16)]

Author's Comment:

• The branch-circuit circuit breaker overcurrent protection is based on motor's FLC [240.6(A), 430.6(A)(1), 430.52(C)(1), and Table 430.248].

• The circuit equipment grounding conductor must be sized to the 45A overcurrent protection device”8 AWG [Table 250.122], but it's not required to be sized larger than the circuit conductors”10 AWG.

Example: What size branch-circuit conductor and overcurrent protection device is required for a 7½ hp, 230V, three-phase motor with 60ºC terminals?

Solution:

Motor FLC = 22A [Table 430.250]

Conductor Size = 22A × 1.25

Conductor Size = 27.50A

Note: The branch-circuit short-circuit and ground-fault protection device using an inverse time breaker is sized at 60A in accordance with 430.52(C)(1) Ex 1:

Circuit Overcurrent Protection = 22A × 2.50

Circuit Overcurrent Protection = 55A

Answer: A 10 AWG conductor rated 30A at 60°C [110.14(C)(1) Table 310.15(B)(16)] and a 60A (next size up from 55A) overcurrent protection device [240.6(A)].

Q5. What is the proper method for sizing circuit conductors that supply several motors according to the NEC?

A5. Circuit conductors that supply several motors aren't permitted to be sized smaller than the sum of the following [430.24]:

(1) 125 percent of the full-load current of the highest rated motor

(2) The full-load current ratings of other motors

Example: What size feeder conductor is required for two 7½ hp, 230V, three-phase motors, if the terminals are rated for 60°C?

Solution:

Motor FLC = 22A [Table 430.250]

Motor Feeder Conductor = (22A × 1.25) + 22A

Motor Feeder Conductor = 49.50A

Answer: 6 AWG rated 55A at 60°C [110.14(C)(1), Table 310.15(B)(16)].

Author's Comment:

• The feeder overcurrent protection device (inverse time circuit breaker) must comply with 430.62 as follows:

Step 1: Determine the largest branch-circuit overcurrent protection device rating [240.6(A) and 430.52(C)(1) Ex 1]:

22A × 2.50 = 55A, next size up 60A

Step 2: Size the feeder overcurrent protection device in accordance with 240.6(A) and 430.62:

Feeder Inverse Time Breaker: 60A + 22A = 82A, next size down, 80A

• The next size up protection rule for branch circuits [430.52(C)(1) Ex 1] doesn't apply to motor feeder short-circuit and ground-fault protection device sizing.

|