|

Electrical safety is our key concern and I'm always looking out for information that will help keep the industry safe. I wanted to pass along to you a report written by Ed Lethert, concerning a marina-related addition to the 2020 National Electrical Code - Section 555.35(B) Leakage Current Measurement Device. I hope you find it has value.

A Marina-Related Addition to the 2020 National Electrical Code

by Ed Lethert, Electric Shock Drowning Safety Specialist

The National Fire Protection Association takes seriously the possibility of dangerous electrical currents in waters around docks where electrical equipment is in use. This concern extends to use of shore-provided electrical power aboard recreational boats, known commonly as "shore power." The practical safeguarding of individuals in the marina/dock environment is accomplished by means of the rules and requirements set out in the National Electrical Code.

The NEC, revised every three years, has been evolving and continues to do so, and we are seeing boating-related additions and revisions with each new edition. This paper addresses one addition that will be included in the 2020 NEC. Let's begin by reviewing the new language which includes a requirement and two accompanying explanatory paragraphs in the form of informational notes. For those familiar with the NEC, note that the 2020 edition has moved the requirements of Section 555.3 to the new Section 555.35.

555.35(B) Leakage Current Measurement Device.

Where receptacles supply shore power to boats, a leakage current measurement device shall be available and be used to determine leakage current from each boat that will utilize shore power.

Informational Note No. 1: Leakage current measurement will provide the capability to determine when an individual boat has defective wiring or other problems contributing to hazardous voltage and current. The use of a test device will allow the facility operator to identify a boat that is creating problems. In some cases a single boat may cause an upstream GFPE device protecting a feeder to operate even though multiple boats are supplied from the same feeder. The use of a test device will help the facility operator prevent a particular boat from contributing to hazardous voltage and current in the marina area.

Informational Note No. 2: An annual test of each boat with the leakage current measurement device is a prudent step toward determining if a boat has defective wiring that may be contributing hazardous voltage and current. Where the leakage current measurement device reveals that a boat is contributing hazardous voltage and current, repairs should be made to the boat before it is permitted to utilize shore power.

The term leakage used in this paper describes the alternating current that is injected (or leaks) into the water as the result of a fault, an electrical wiring error or malfunction, faulty electrical equipment, incompatible electrical equipment, etc. The term leakage used in this paper describes the alternating current that is injected (or leaks) into the water as the result of a fault, an electrical wiring error or malfunction, faulty electrical equipment, incompatible electrical equipment, etc.

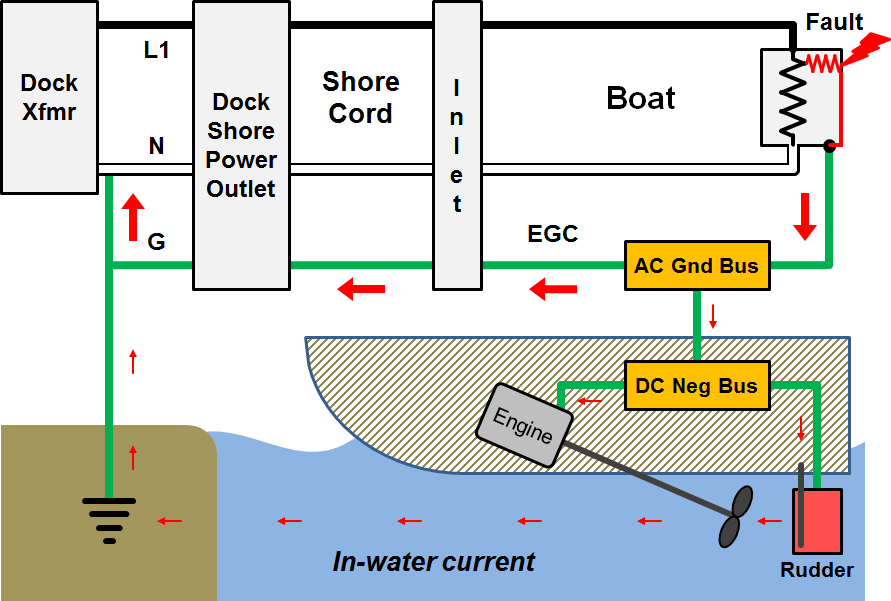

Almost all the fault current (shown by red arrows) will be carried by the EGC (equipment grounding conductor), presuming that it is connected and in serviceable condition.

A very small percentage of the fault current will flow through the water path because the on-board EGC is bonded to the DC system (required by boat wiring standards). The much smaller water-borne or leakage current does not typically constitute a hazard to an individual or other living creature in the water, even when they are close to the source. Note: This article is addressing a new requirement to be included in the 2020 NEC and not the issue of electric shock drowning.

If a fault condition exists onboard the boat and the EGC is not intact, the water can become the primary”and possibly the only”return path for the fault current, in which case a hazardous condition can exist in the water. It is this potentially hazardous leakage current that is being addressed by the NEC. If a fault condition exists onboard the boat and the EGC is not intact, the water can become the primary”and possibly the only”return path for the fault current, in which case a hazardous condition can exist in the water. It is this potentially hazardous leakage current that is being addressed by the NEC.

One practical means for testing a boat for leakage current, as stated in Section 555.35(B), is achieved using a clamp type ammeter. The 2020 NEC will require "leakage current measurement device" which is essentially the same device as the typical clamp ammeter except for being able to accurately measure alternating currents in the milliampere range, or lower. These measuring devices are considerably more expensive than the typical clamp type ammeter and must be handled with additional care, especially where the jaw is concerned.

Figure 1 depicts the scenario envisioned by most when considering use of a clamp type meter to measure the current leaking into the water from a boat connected to a shore power distribution system. ALL the conductors in the cord are included so the instrument displays the net difference current of the hot, the neutral, and the ground (EGC). This measurement reveals current is flowing, either into or out of the water, via the EGC (that is bonded to the boat's submerged metal surfaces). Figure 1 depicts the scenario envisioned by most when considering use of a clamp type meter to measure the current leaking into the water from a boat connected to a shore power distribution system. ALL the conductors in the cord are included so the instrument displays the net difference current of the hot, the neutral, and the ground (EGC). This measurement reveals current is flowing, either into or out of the water, via the EGC (that is bonded to the boat's submerged metal surfaces).

Alas, any such current reading is simply the net difference of currents flowing into the water and out of the water. It could be indicating that current is flowing into the water due to a fault condition on the boat being tested or current is flowing out of the water due to one or more fault conditions on nearby boats or the dock electrical system. It could also be a combination of the two conditions. Simply stated, this measurement does not identify the source or sources of the current, only that current is flowing in the water. Regardless of the source or sources, significant levels of current so measured may be an indication of dangerous conditions (i.e. voltage gradients) in the water near the boat and strongly suggest that further investigation is required.

Performing the measurement with power to the boat first switched on and then switched off may be of some help. If the power ON current is greater than the power OFF current, the boat may be an emitter. If they do not differ, the boat may be a receptor. This measurement can be deceptive when the boat being tested is only one of several boats connected to the same feeder or source, and where any number of them could also be producing significant leakage current.

The evaluation is made more complex when the shore power distribution is via a 125/250V split phase, multi-wire system, by far the most common in small and medium sized marinas. Leakage current produced by a boat powered from the L1 feeder conductor can be partially, even completely, cancelled”thus masked”by leakage current produced by a boat powered from the L2 feeder conductor. The same complexity can be found aboard boats served by 50A-125/250V service where faults on both L1 and L2 can mask each other. The result is often misleading and cannot be relied upon to identify a possible hazard. This can be a very challenging dynamic as boats come and go, connecting to and disconnecting from the shore power system.

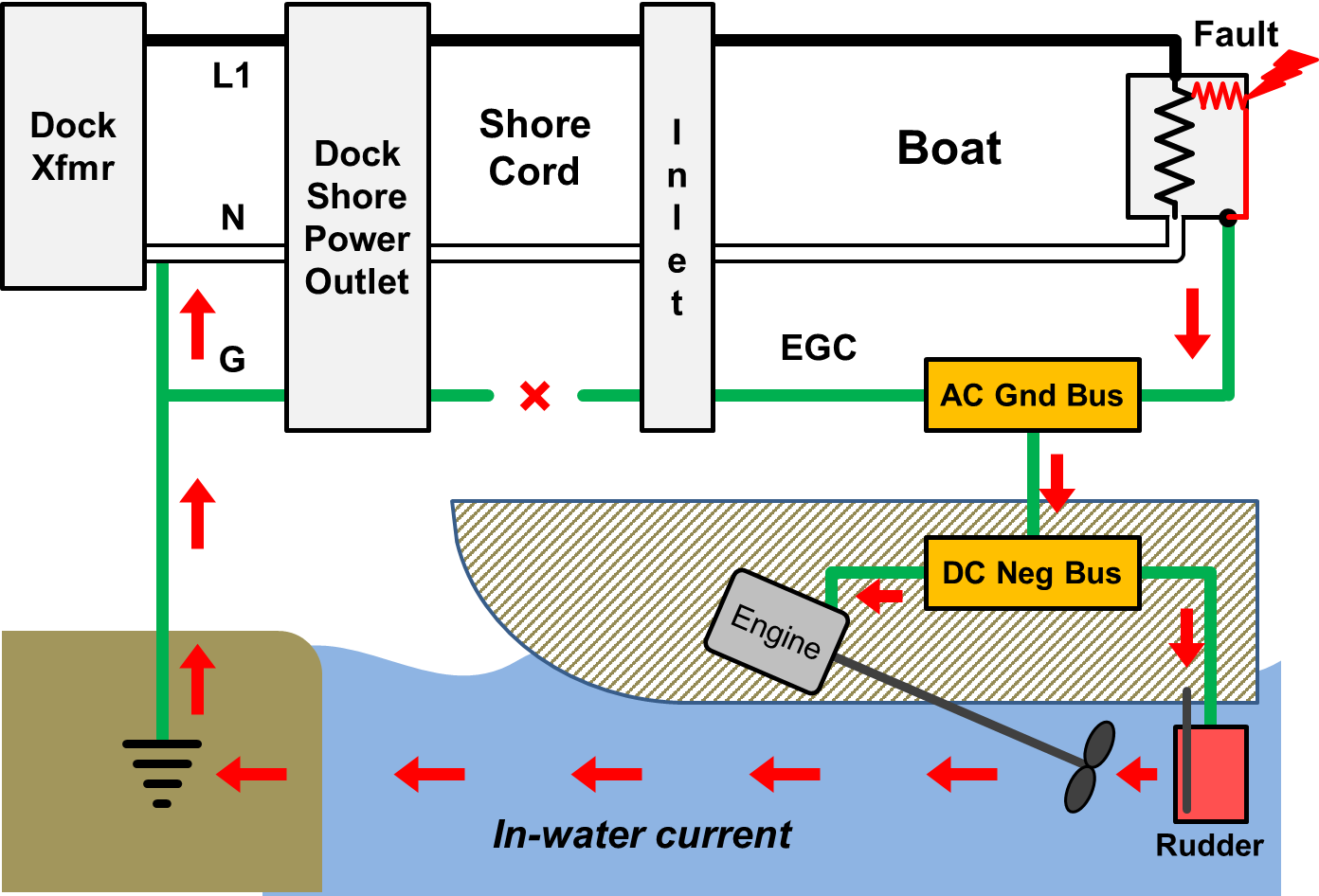

Figure 2 depicts a workable method for investigating and locating the existence of one or more fault conditions (leakage current) aboard a boat, even in a crowded marina. Note that a breakout cord is required as the real leakage from (caused by) the boat under test is the net difference current between only the ungrounded and grounded (hot and neutral) conductors of the boat being tested. Where shore cords have two hot conductors (50A-125/250V cords), both L1 and L2 must be included in the clamp with the neutral. In all cases the EGC (the green-insulated grounding conductor) must not be included. Figure 2 depicts a workable method for investigating and locating the existence of one or more fault conditions (leakage current) aboard a boat, even in a crowded marina. Note that a breakout cord is required as the real leakage from (caused by) the boat under test is the net difference current between only the ungrounded and grounded (hot and neutral) conductors of the boat being tested. Where shore cords have two hot conductors (50A-125/250V cords), both L1 and L2 must be included in the clamp with the neutral. In all cases the EGC (the green-insulated grounding conductor) must not be included.

Performing measurements with a breakout cord requires disconnecting the boat's shore cord to insert the breakout cord. For the measurement to be meaningful, it must be made with power applied to the boat's AC system and on-board loads running. This is particularly important with larger loads such as motors, compressors, heating elements, etc. The procedure must be performed for each shore cord serving the boat and for each load served by that cord.

The breakout cord solution provides a practical (albeit moderately costly) means for determining the existence of fault conditions on-board a boat. Breakout cords are needed for all connection options available in the marina. This will include, at a minimum in most cases, adapters for 30A-125V, 50A-125V, and 50A-125/250V services. There could be others required in larger marinas and/or marinas serving larger boats. Figure 3 pictures an example of a leakage clamp meter and basic breakout cord kit.

Wiring errors aboard the boat can give the appearance of an equipment fault. The boat's wiring system, including shore cord(s), must be tested to ensure compliance with the requirements of American Boat and Yacht Council (ABYC) Standard E-11 "AC and DC Electrical Systems on Boats." Interestingly, this requires another series of tests not covered here. Wiring errors aboard the boat can give the appearance of an equipment fault. The boat's wiring system, including shore cord(s), must be tested to ensure compliance with the requirements of American Boat and Yacht Council (ABYC) Standard E-11 "AC and DC Electrical Systems on Boats." Interestingly, this requires another series of tests not covered here.

While clamping the entire shore cord (Figure 1) can indicate that there is alternating current flow in the water, investigation of any one boat as a potential source of leakage current requires use of a breakout cord and evaluation of the boat's on-board wiring and electrical loads.

Where ground-fault conditions exist on board, testing and troubleshooting is made considerably more difficult when the shore power will not remain energized. Marinas and boatyards will require one or more shore power receptacles (of each type in use) that include overcurrent protection, but not ground-fault protection, to facilitate the testing process where boats would otherwise trip the 30 mA ground-fault protection. Access to and use of these non-GFP receptacles should be limited to qualified service personnel.

In summary, overall clamping of shore cords in a marina can identify the existence of hazardous alternating currents in the water and is a valid means for identifying potentially dangerous conditions. A more detailed analysis, such as described herein, is needed to identify a specific problem boat and ultimately the cause of the problem on board the boat. This is a new challenge that marina operators will face as they update their electrical systems to the new 2020 NEC requirements, along with marine service technicians that work on boats.

Some important questions remain with regard to the requirements of the NEC and expectations of the AHJ as it relates to marine leakage current and its measurement.

- What is an acceptable specification for a "leakage current measurement device" considering that the AHJ must be satisfied that the instrument selected meets the intent of the Code before approving it?

- Is there a published specification for such a device that will be acceptable to the AHJ?

- Is there a list of acceptable devices that will be acceptable to the AHJ?

- Has the term leakage current (as associated with boats connected to shore power) been clearly defined, standardized, and understood by all involved in the process?

- What testing procedures or protocols are applicable?

- Have testing procedures been defined and published?

- Where can acceptable testing procedures/protocols be found?

- Where does one find instruction and training on how to perform the necessary (and yet to be identified) testing procedures/protocols?

- When will the 2020 requirement be considered applicable to a specific marina?

Download and print the article here.

About Ed. Ed Lethert is an Electric Shock Drowning Safety Specialist living in Minneapolis, Minnesota. He has devoted much of his time in recent years to addressing issues associated with electric shock drowning (ESD). He's a retired electronic technician, technical consultant, electrical project manager, and electrical instructor. His activities include promoting awareness of ESD with presentations to marina associations, sheriffs departments and other groups, promoting the installation of ESD warning signs, distribution of ESD educational materials, etc. Ed is a member of the Electric Shock Drowning Prevention Association.

elethert@gmail.com

http://www.electricshockdrowningmn.com/

|